Pressure Types: A Video Explanation

In the pressure calibration business, we get the question "What's the difference between gauge pressure and absolute pressure?" often. The answer is simple and comes down to what the pressure is referenced to. Essentially, all pressure is measured as a difference between a reference pressure and a measured pressure. For gauge pressure, the reference is ambient atmospheric pressure; for absolute pressure, the reference is absolute zero pressure or the absence of pressure.

The following video offers a graphical representation of the differences between gauge and absolute pressure, as well as barometric, bidirectional, and vacuum pressure.

Absolute Pressure

Absolute pressure is zero-referenced against a perfect vacuum. It is used to measure pressure relative to absolute zero. The ambient barometric pressure on earth is measured as an absolute pressure. It is the difference between the zero pressure of outer space and the pressure created by the atmospheric gases that cover the earth, held there by gravity.

When there is nothing within a space, there is nothing to create a pressure. This is the baseline used for comparison in an absolute pressure measurement. This means the lowest reading an absolute pressure instrument can reach is zero - absolute pressure cannot be negative. However, zero absolute pressure is virtually impossible to achieve. This and other complexities involved with zeroing absolute sensors is explained in the white paper: "Everything You Wanted to Know About Setting Zero on an Absolute Pressure Transducer, but Were Afraid to Ask."

Gauge Pressure

Gauge pressure is referenced against atmospheric pressure. Gauge pressure is used when it is important to know how much a pressure differs from atmospheric pressure. For example, a vessel containing a pressurized gas is subjected to a force on the interior vessel walls. The exterior walls of the vessel also experience a force from the ambient atmospheric pressure. The difference between these pressures must remain below the burst pressure of the vessel, or the vessel could explode. This difference is called gauge pressure. When a gauge sensor's pressure port and reference port are both open to atmospheric pressure, the reading should be zero.

Low gauge pressure measurement and calibration can be tricky. As a leader in low pressure instruments for many years, Mensor has developed special techniques to characterize and calibrate gauge pressure instruments with full scale ranges below 5 psi. The white paper "Low Pressure Measurements" describes these techniques and limitations.

Differential Pressure

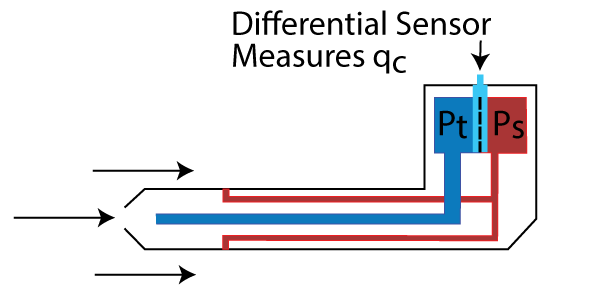

By convention, what we call differential pressure is similar to gauge pressure in that it also has two sides - the low side and the high side. However, the low side (sometimes called the line pressure) is not always atmospheric pressure. The low side can be atmospheric or any other pressure, limited by the pressure rating of the sensor. The high side can be higher than the low side, resulting in a positive differential, or lower than the low side, resulting in a negative differential. This is complicated by the fact there may be an offset at different line pressures. This type of sensor is sometimes used to measure flow across a restriction in a pipe; the differential pressure across the restriction is proportional to the flow.

Another good example of this type of sensor is the Qc sensor in Mensor's CPA8001 Air Data Test Set, which measures an aircraft's airspeed. Mensor has developed a way to increase the accuracy of this type of sensor to compensate for different line pressures.

Vacuum Pressure

Vacuum pressure may mean different things to different people. We define vacuum pressure as a sub-atmospheric pressure that is measured relative to the ambient atmospheric pressure. It is expressed as a positive number. The statement "29 inches of Hg vacuum" means the pressure being described is 29 inches of mercury (Hg) below atmospheric pressure. This is equivalent to -29 inches of mercury gauge pressure. The term vacuum in this context is a common way to describe these sub-atmospheric pressures. This is especially true in the HVAC and automotive industries.

Others may refer to vacuum pressure as any pressure - either absolute or gauge - that is less than ambient atmospheric pressure.

Bidirectional Pressure

Like gauge pressure, bidirectional pressure is zero-referenced against atmospheric pressure. However, bidirectional pressure extends above and below atmospheric pressure. The indication of pressure below atmospheric pressure is denoted with a negative (-) sign and pressure above is indicated with a positive (+) sign, or the sign is omitted. A bidirectional range can be symmetrical (the magnitude of the negative portion is equal to the positive portion) or non-symmetrical (the negative and positive portions are not equal in magnitude). Symmetrical ranges like -15 to +15 are sometimes written as +/-15, and non-symmetrical ranges show the negative and positive portion, such as -15...100. A good example of an application here is in monitoring rooms in hospitals or nuclear power plants, where it is desirable to have the room at either a lower or higher pressure than the exterior.

A bidirectional transducer is really just a gauge transducer that has been calibrated and ranged to include a negative component below atmospheric pressure. As with gauge pressure, the calibration of pressure spans below 5 psig require special consideration.